Manufacturing Process of Nut and Screw Fasteners

Cold heading- Wire is taken care of from a mechanical loop through a prestraightening machine. The fixed wire streams straightforwardly into a machine that consequently cuts the wire at an assigned length and kick the bucket cuts the top of the screw clear into a prearranged shape.

Thread rolling - When cold headed, the screw spaces are naturally taken care of to the string cutting passes on from a vibrating container. The container directs the screw spaces down a chute to the kicks the bucket, while ensuring they are in the right feed position.

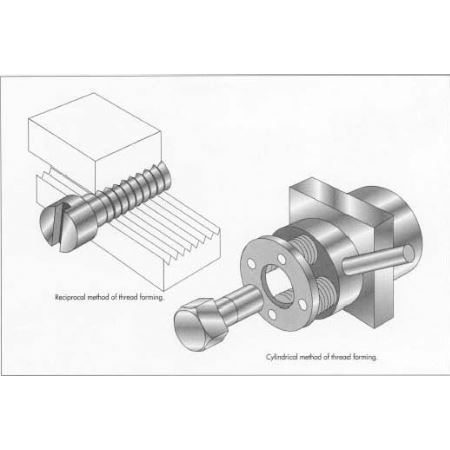

Thread rolling - The clear is then cut utilizing one of three procedures. In the responding pass on, two level bites the dust are utilized to cut the screw string. One bite the dust is fixed, while different moves in a responding way, and the screw clear is moved between the two. At the point when a centerless tube shaped kick the bucket is utilized, the screw clear is moved between a few round passes on so as to make the completed string. The last technique for string moving is the planetary rotational kick the bucket cycle. It holds the screw clear fixed, while a few bite the dust cutting machines move around the clear.

Quality Control - It depends on the application and use of the bolt. Packing and/or Stocking - After quality control to ensure uniformity and consistency, the bolts are packaged for shipment as per the requirement.