- Have any problems?

- sales@anankafasteners.com

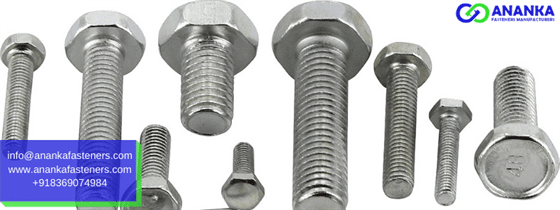

ASTM A276 Type 321-2 Bolt, Nuts, Washers Manufacturer in India

ASTM A276 Type 321-2, ASTM A276 Type 321-2 Bolt, Nuts Manufacturer in India – Ananka Group

ASTM A276 Type 321-2 refers to a variation of Type 321 stainless steel under the ASTM A276 specification, which covers stainless steel bars and shapes. In this, the scopes of specification involve bar and various shapes of stainless steel. 321-2 type is quite similar to the standard type 321, but with certain mechanical or surface finishing requirements especially for some of the application requirements such as extra strength, toughness, and much better surface characteristics.

Table of Contents

ToggleType 321-2 is used for high temperature purposes because of the stability imparted by the presence of titanium which resists carbide precipitation thus, it has direct relevance to parts exposed to 800-1500°F (427-816°C) temperatures.

Key Features of ASTM A276 Type 321-2

Stabilization by Titanium: Like Type 321, Type 321-2 has titanium, which provides protection against intergranular corrosion especially after having been exposed to heat.

Resistance to Corrosion: Oxidation resistant at elevated high temperatures and general corrosion environments, although not as good as some of the higher Chromium/Nickel grades.

Strength and Toughness: Strong, with good ductility up to elevated temperatures and mechanical stresses.

Better Surface Finishing Options: The “2” designation often corresponds to specialized treatments or finishing options such as enhanced surface finishes or additional mechanical properties for particular applications.

Applications:

High Temperature Applications: Components in chemical processing and in oil and gas industries, where high temperatures are involved, and in the power generation, particularly in the exhausts of steam and gas turbines.

Automobile and Aerospace Exhaust System: The material is widely used for exhaust manifolds, mufflers, and other components due to its excellent resistance to oxidation at high temperature.

Welded Components: Is recommended for welded applications since after welding, it does not degrade and there is no possibility of intergranular corrosion.

Mechanical Properties: Equivalent to Grade 321:

Tensile Strength: ≥ 75 ksi (515 MPa)

Yield Strength: ≥ 30 ksi (205 MPa)

Elongation: 40% minimum in 2 inches (50.8 mm)

ASTM A276 Type 321-2 is an enhanced grade version of Type 321, equivalent to Type 321 in resistance to intergranular corrosion and other mechanical properties favorable and even at elevated temperatures. It is used primarily in situations where a surface quality or another mechanical property is considered important for the job application.

ASTM A276 Type 321-2 Chemical Composition

| Grade Symbol | UNS Number | Elements | Composition, % |

|---|---|---|---|

| Type 321 | S32100 | Carbon | 0.08 max |

| Manganese | 2.00 max | ||

| Phosphorus | 0.045 max | ||

| Sulfur | 0.030 max | ||

| Silicon | 1.00 max | ||

| Chromium | 17.00 – 19.00 | ||

| Nickel | 9.00 – 12.00 | ||

| Titanium | 5×(C+N)-0.70 |

ASTM A276 Type 321-2 Mechanical Composition

| Property | Value |

|---|---|

| Finish | Hot-Finished & Cold Finished |

| Tensile Strength, min, ksi [MPa] | 75 [515] |

| Yield Strength, min, ksi [MPa] | 30 [205] |

| Elongation in 2 in. [50mm] or 4D, min, % | 40 |

| Reduction or Area, min, % | 50 |

| Brinell Hardness Number, HBW | …. |

ASTM A276 Type 321-2 Bolt, Nuts, Washers Manufacturer in India

| The city we supply ASTM A276 Type 321-2 Bolt, Nuts, Washers: | |||||

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

ASTM A276 Type 321-2 Bolt, Nuts, Washers Manufacturer in India

| Manufacturer Exporter of ASTM A276 Type 321-2 in the following countries: | |||||

|---|---|---|---|---|---|

| Saudi Arabia | Kazakhstan | Zimbabwe | Netherlands | Sweden | |

| Afghanistan | Belgium | UAE | Israel | Europe | |

| New Zealand | Mexico | Canada | Venezuela | United Kingdom | |

| United States | South Africa | Malaysia | Poland | Germany | |

| Singapore | Sri Lanka | Australia | Brazil | Ireland | |